Firearms Section

The Firearms section performs a diverse array of firearms tests in addition to comparing toolmarks imparted to firearms related evidence. Analysts inspect firearms for safety and test fire to collect bullets and cartridges marked by the firearm. While our most common request is to determine if a firearm is the source of either bullets or cartridge cases, many additional types of examinations and comparisons may be performed to assist in your investigation. Any item tested in the Firearm’s Section but not previously swabbed for DNA will become ineligible for future DNA testing.

Submission of Firearms Evidence:

- Loaded firearms should not be submitted to the Forensic Science Division. All ammunition, magazines and cartridges should be removed and packaged separately for submission (they can be submitted in the same package as the firearm). If assistance is needed with making firearms safe, consult the Firearms Section of the laboratory or a range master.

- A firearm should not be disabled by disassembling any part or mechanism.

- Do not mail loaded weapons!

- Notes/diagrams should be taken by the person collecting the firearm and a copy included with the firearm (note – diagrams should be drawn from the perspective of the shooter):

- Revolvers –cylinder position, (mark the cylinder on either side of the top strap as found), loading index (diagram location of cartridges/fired cartridge cases in the chamber in relation to the marks on either side of the top strap), and hammer position (forward, safety notch,½ cock, full cock)

- Semi-automatic firearms – magazine (in or out), round (chambered or not), hammer position (if external), slide position (forward or back), and location of any jammed cartridge/fired cartridge case.

- Multi-barreled firearm – chambers (empty or loaded), hammer(s) position, breech (open or closed).

- Package firearms to prevent altering the evidence in any way, to prevent cross contamination, and to preserve potential fingerprints or DNA evidence.

- When removing a bullet from drywall, wood, or other material, cut around the bullet and submit – avoid using metal devices that may mark the bullet.

- Bullets and cartridge cases should be dried before packaging as moisture will corrode the metal and may destroy markings of value.

- Bullets (especially lead) should be packaged to protect them from being marked in transport.

- Cartridge cases and bullets should be packaged in an envelope or box. Heat-sealed plastic bags and zip-lock bags are acceptable for packaging as long as there is no moisture.

- Evidence for distance determination examination should be packaged carefully with paper laid between layers to keep gunpowder particles in place and to prevent transfer.

- Items that have blood or other biological fluid must be air-dried before packaging and labeled appropriately with a BIOHAZARD label.

Crime Scene Assistance:

Members of the Firearms Section may be requested to assist FIS (the Forensic Investigation Section) at crime scenes. In this capacity, members of the Firearm Section may assist with examinations such as:

- Trajectory measurement of the bullet's flight path before impact.

- Assistance with firearms, including unloading and making them safe to package and submit to evidence.

- Other general assistance at the direction of a scene investigator.

Firearms Testing Options:

No Gun - Examinations:

When fired bullets, cartridge cases, or shot shells are collected with no firearm to compare to they may be compared to one another to determine if they were fired from the same unknown firearm or to possibly determine how many firearms were involved in the crime.

General Rifling Characteristics (GRC) Examinations (Performed on Bullets Only):

In cases where a weapon is not available for comparison to a fired evidence bullet, the laboratory may be able to provide a list of weapons that could have fired the bullet. By examining the class and rifling characteristic imparted to a fired bullet (caliber, weight, shape, construction of the bullet, direction of twist, number of land and grooves, and widths of land and grooves) and checking these against the Association of Firearm and Tool Mark Examiners (AFTE) General Rifling Characteristics (GRC) Database, a list of weapons that may have fired the bullet can be provided.

Firearm Function/Operation:

Firearms may be examined to determine their ability to function as designed. Included in this examination is an evaluation if the firearm can fire multiple projectiles in a single pull of the trigger (Machine Gun, NRS 202.253.6). This type of examination may be important in cases such as accidental shootings, suspicious suicides, etc.

Firearms Comparisons:

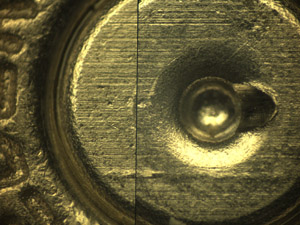

Fired evidence bullets, cartridge cases, and shot shells can be microscopically compared to test fired bullets, cartridge cases, or shot shells from a suspected firearm to determine if they were, or were not fired from that particular gun.

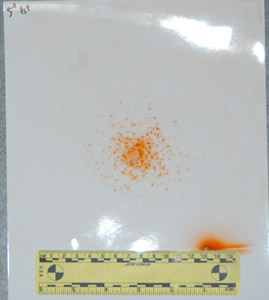

Muzzle to Target Distance Determination:

By examining gunshot residue patterns around a bullet hole in a garment or other objects of evidence, and comparing this pattern to test patterns produced using the firearm and ammunition in question, an estimate of the distance from muzzle to target can be given (usually given as a range of distance).

- This type of analysis generally requires the questioned firearm and ammunition for testing.

- Other information such as autopsy reports, crime scene photographs showing any bullet holes or wounds and any witness statements can help to determine the muzzle to target distance.

IBIS (Integrated Ballistic Identification System)/NIBIN (National Integrated Ballistic Information System):

IBIS is a digital imaging system used to capture images of fired cartridge cases from crime scenes and from firearms seized in conjunction with criminal investigations. The NIBIN database compares these images against other images from fired cartridge cases to identify investigative links between firearms and crime scenes. The Forensic Science Division will accept all semi-auto pistols, rifles, and shotguns for entry into NIBIN.

The Forensic Science Division will not enter test fired cartridge cases from revolvers, derringers, or muzzle loaders into NIBIN. Should there be a special request to enter revolver cartridge cases, please contact the Firearms Supervisor directly. The IBIS system at WCSO-FSD cannot image bullets. Also, officer firearms are not eligible to be entered into the NIBIN database.

Images of fired and test fired cartridge cases will be searched against the local NIBIN database and the default regions, which are controlled through ATF. (If you suspect the firearm evidence could be linked to a different region, please include that information on the testing request.)

NIBIN Sites in our Default Region:- CALIFORNIA

- ATF – San Francisco FD – Dublin, CA

- Alameda County, CA SO Crime Lab

- CA DOJ – Fresno (Decommissioned Site)

- CA DOJ – Sacramento (Decommissioned Site)

- Contra Costa County, CA SO Crime Lab

- Fresno County, CA SO (Decommissioned Site)

- Fresno, CA PD

- Fairfield, CA PD

- Oakland, CA PD Lab

- Sacramento County, CA DA Lab (Decommissioned Site)

- Sacramento County, CA SO Lab

- Sacramento, CA PD

- Salinas, CA PD

- San Francisco, CA PD Crime Lab

- San Joaquin County, CA SO

- San Mateo County, CA SO Forensic Lab

- Santa Clara County, CA DA’s Crime Lab

- Santa Maria, CA PD

- Stanislaus County, CA SO

- Stockton, CA PD

- IDAHO

- Idaho State Police – Coeur d’Alene (Decommissioned Site)

- Idaho State Police – Meridian

- NEVADA

- Las Vegas, NV Metropolitan PD

- Washoe County, NV SO Lab

- UTAH

- Utah DPS – Salt Lake City

- Utah State Crime Lab – Ogden (Decommissioned Site)

- Zones 3 (SW) & 4 (NW)

- ATF Labs

- ATF Transportable Units

- FBI Lab

If a different region is searched, the searched region will be included in the testing report.

Serial Number Restoration:

Virtually any object made of metal, that has had a stamped serial number removed or defaced, has the possibility of being restored. Serial numbers, which have been stamped into a variety of items, in addition to firearms, can all potentially be restored. During the process of number stamping, the metal underlying the number is placed under greater stress than the surrounding metal. Even though a person may file or grind away at this number until it is no longer visible, portions of the stressed metal from the stamping can remain. In the laboratory, the defaced surface, where the serial number was, is treated with one or several chemical etching solutions. These chemical-etching solutions will cause the stressed and unstressed metals to behave differently. The different behavior is a chemical reaction visible at the sites of the stressed metal. Restoration is not always obtained. In some cases, the eradication process may have been sufficient to completely remove the stressed metal in some or all areas. This can result in a partial restoration or no restoration at all.

Methods utilized:

Database Related Methods

- Fired Cartridge Case Triage

- NIBIN Entry

- Correlation Review

- Manual Comparison

Firearms Analysis Related Methods

- Ammunition Component Examination

- Firearm Examination (Function/Operation)

- Test Firing

- General Rifling Characteristics

- Microscopic Comparison

- Serial Number Restoration

- Distance Determination